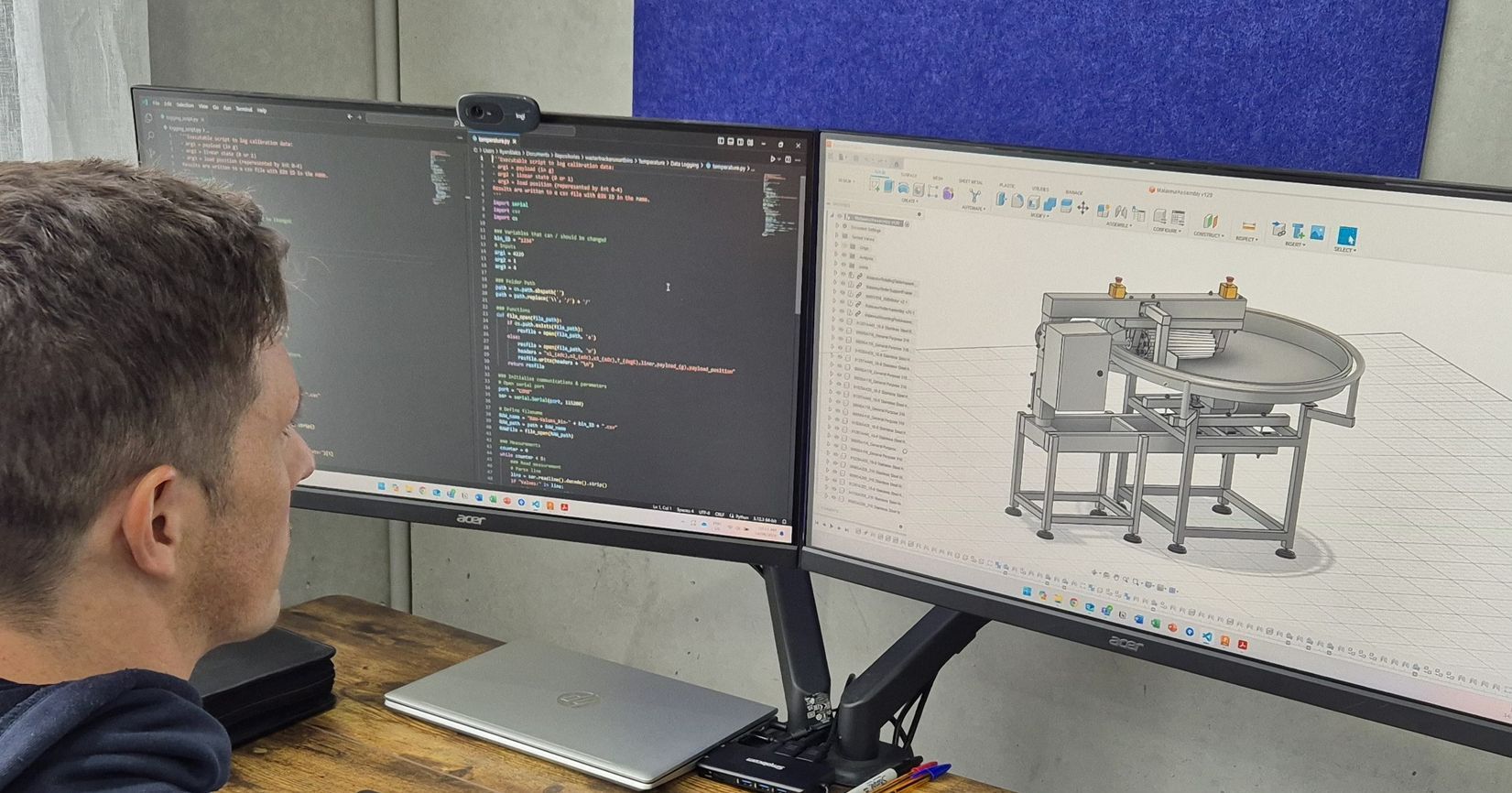

Bringing your visionary concept to life.

Your Partner in Complex Technical Innovation.

We are an engineering, modelling and advisory firm specialising in innovation. We engineer the complex products that don’t exist yet, the first-of-a-kind designs and the early-stage projects & prototypes.

All our projects are unique and require a custom approach. We specialise in supporting inventors, change-makers and visionary thinkers to turn their concepts in real-world products & projects.

Our Services

Our Customers Are Innovators

Our Clients

Client Testimonials

A word from our current and past clients.

Past Projects

We have a track record of delivering complex engineering innovation across a wide array of industries. Watch our case study video to learn about some example past projects.

Projects Delivered

20+

Over 20 complex projects delivered in the past 2 years.

Different Industries

7

Our services are industry agnostic.

45-minute Project Discovery Call

Join us for a discovery call to explore how our expertise can drive your innovation forward. We'll discuss your project goals, identify challenges and explore tailored solutions to help you bring your ideas to life.